EN 17206: 2020

Entertainment technology - Machinery for stages and other production areas - Safety requirements and inspections

“Utilising a load arrestor alongside a primary lifting hoist, delivers an independent safety function which provides complete redundancy.”

In June 2020, the new entertainment standard, “EN 17206:2020 Entertainment technology - Machinery for stages and other production areas - Safety requirements and inspections” was published in place of previous entertainment standards “EN 7906-1:2005” and “EN 7905-1:2001”.

The purpose of EN 17206:2020 is to produce European wide specifications for the design, manufacture and installation of lifting and load bearing equipment within the entertainment industry. The standard applies to all machinery, machinery installations and machinery control systems which are used within assembly, staging and production facilities for events and theatrical productions. Such facilities include; theatres, exhibition halls; film, television and radio studios, concert halls, schools, bars, discotheques, open air stages and any other rooms used for shows or events.

EN 17206:2020 applies to permanent and temporary installations of lifting and moving equipment within the entertainment industry. Typical applications of the standard include; acoustic doors, auditorium elevators, compensating elevators, cycloramas, fly bar systems (manual and motor driven), lighting bars, movable lighting towers, movable proscenium arches, orchestra elevators, performer flying systems, point hoists, revolving stages and turntables, scenery storage elevators, side stage and rear stage shutters, stage elevators, stage wagons, tiltable stage floors and trap elevators.

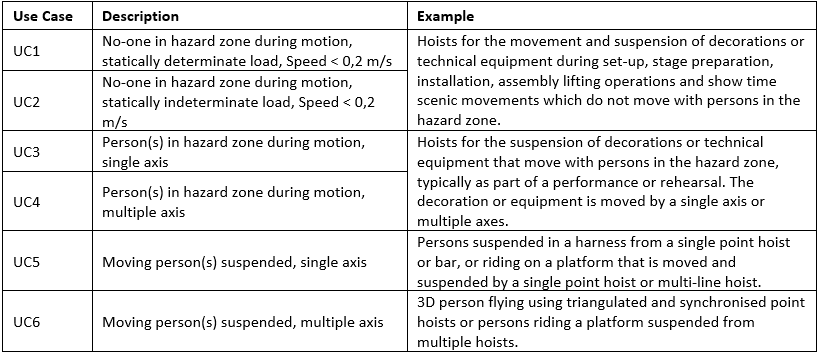

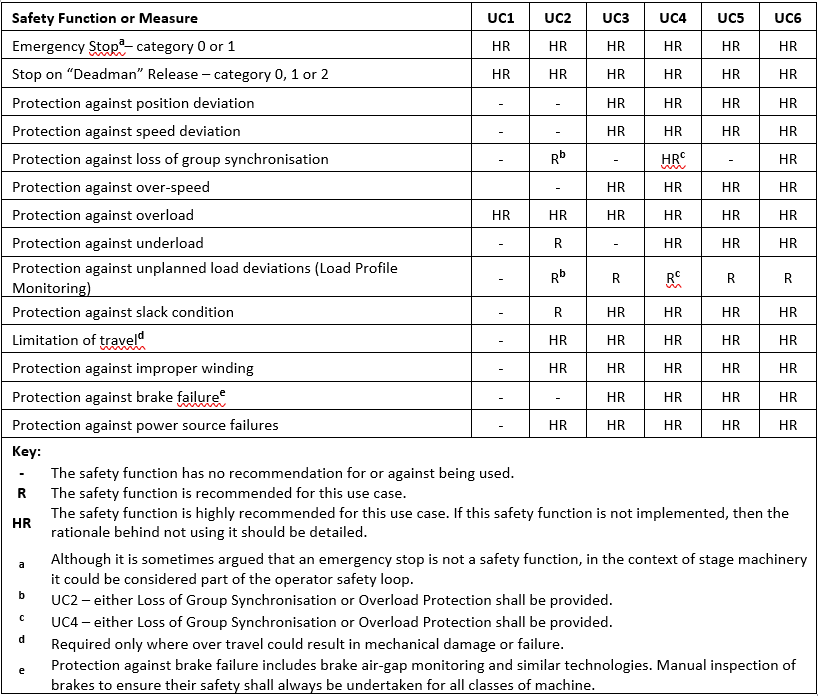

EN 17206:2020 Annexes B & C define use cases reflecting common machinery risk scenarios (Table 1) as well as guidance on the safety functions to be implemented for each use case (Table 2).

Table 1: Use cases for upper machinery

Table 2: Recommended safety functions for upper machinery

For Use Cases 3, 4, 5, and 6, it is highly recommended that a safety function is implemented to maintain a safe state for the machine in respect of brake failure. Utilising a Guard Load Arrestor alongside the primary lifting hoist, provides an independent safety function which provides complete redundancy.