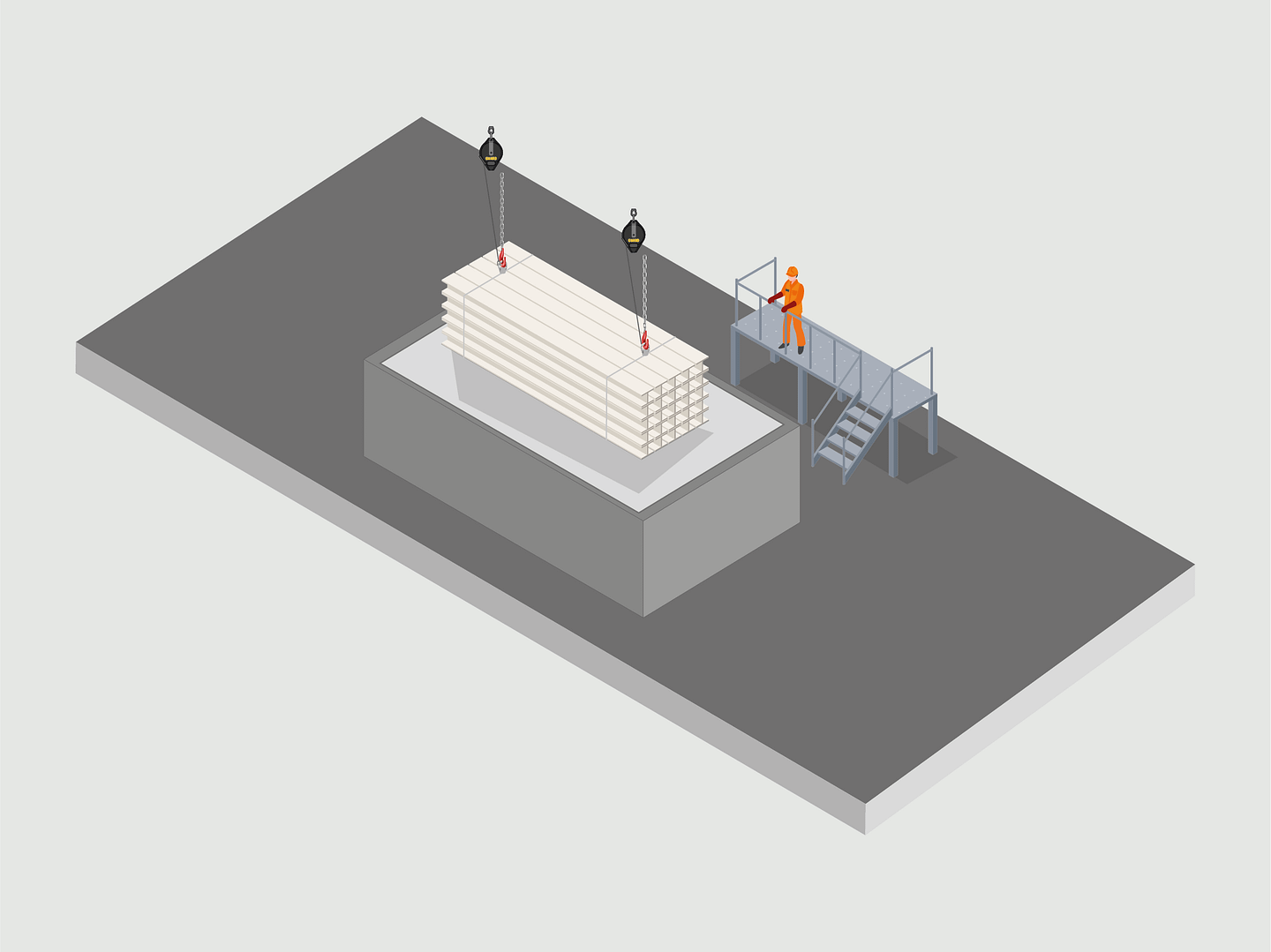

Materials being dropped during the dipping process could be a costly failure, not to mention the risk to any personnel who may be nearby. More and more, galvanizing plants are installing load arrestors alongside their primary lifting equipment, as a dependable safeguard against the material being dropped, in case of a failure with the primary system.

In this application, one (or more) Guards are fitted to a secure anchor point, above the dipping bath, with the Guard's end shackle fitted to the material's cradle. The Guard's cable automatically extends and retracts, like a fall arrester, following the movement of the load. This means the materials are always protected, even during raising/lowering, without the need for the Guard's cable to be routinely reattached - just leave it in place and let it do its work. A simple and cost-effective safeguard.

What's more, Guard load arrestors can be fitted with stainless steel cable and feature corrosion resistant components, helping them withstand the harsh environment within galvanizing plants.

Whatever you do, make sure you #GuardAgainstGravity.

View the products here.