Spring failure is one of the biggest risks when using tool balancers. If tool balancers fail, would there be risk of injury or damage to the equipment? Some tool balancers include a safety back-up, but many don't. Even with an incorporated safety mechanism, what happens if the line itself is severed? We are increasingly finding that risk assessments reveal the need for an extra safeguard for tool balancer installations.

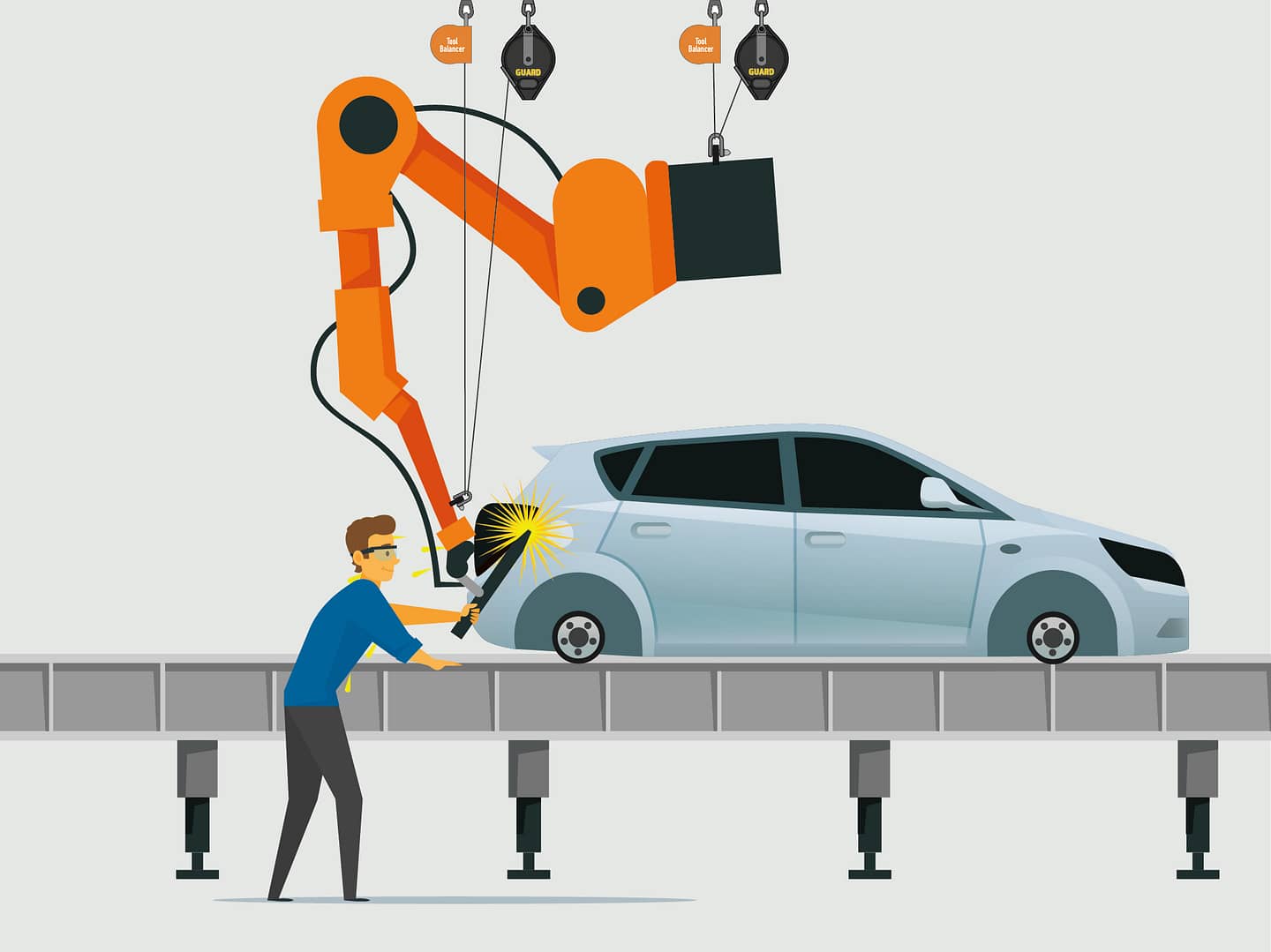

Guard load arrestors can be the perfect solution; the Guard's cable automatically extends and retracts, allowing the equipment to move freely whilst always been connected to load arrest. It's a simple solution - just anchor the Guard above the equipment to be protected and attach the cable's end to the equipment itself. Should it fall, the Guard will quickly and safely catch the falling gear, thereby preventing damage and potential injury. It's a straight-forward and cost-effective safeguard.

On consideration, when deploying Guard load arrestors in this way, is the activation speed of the Guard. If the activation speed (0.6m per second) is exceeded during general operation then the Guard's brake will still activate, even if the equipment hasn't fallen. It's therefore important to carefully consider this. If you need any assistance at all then please get in touch; we will help you find the right solution.

Whatever you do, make sure you #GuardAgainstGravity.

View the products here.