Case Study: St George’s Hall

Client: St George’s Hall, Bradford Theatres

Problem:

The concert hall’s engineering team reached the conclusion that, to provide a safe system of work, adding-in Guard Load Arrest protection to the system would be the correct solution. However, with St George’s Hall being an old concert hall, the pipe we had to pass the load arrestor’s cable through was extremely narrow and, when researching the project, no obvious answer became apparent to allow the cable, ferrule, thimble & shackle to pass through the pipe from the anchorage point to the truss below within the theatre.

Solution:

The new configuration of the bottom shackles on Guard Load Arrestors means that the shackle can be easily removed from the cable (the pin fits through the thimble), thereby solving part of the problem.

Due to the pipe being so narrow, the standard thimble still wouldn’t pass through the pipe. However, with Guard Load Arrest being the product manufacturer (with a full understanding of the product’s technical file), we were able to change the thimble to a narrow gauge alternative. This allowed the thimble to fit through the narrow pipe and then the shackle be reattached through the thimble.

This solution was achieved by Guard Load Arrest being able to manufacture the solution in accordance with the technical file and provide a solution that worked precisely for the customer.

Guard Load Arrest become official ABTT supporters

Guard Load Arrest are proud to announce they are Industry Supporters for the Association of British Theatre Technicians (ABTT), a membership organisation with backstage and theatre buildings at its heart.

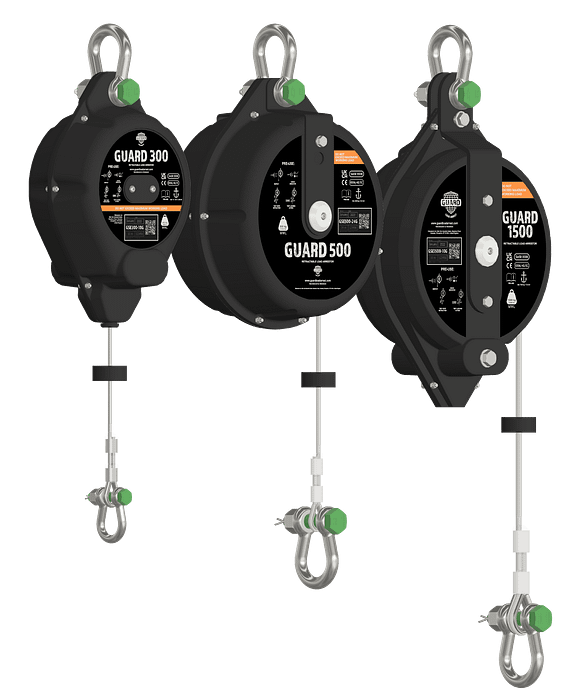

Guard Load Arrest has just launched, offering durable load arrest solutions to the entertainment and industrial sectors. The product range offers protection from 150 kg to 1500 kg, and developments are already underway to expand the range even further. Guard Load Arrest is eager to support organisations within the industry so were keen to sign up for this opportunity with ABTT.

The ABTT is a membership organisation which sets and upholds standards in technical excellence, safety and compliance for theatre and live performance. The organisation is an excellent resource for supporting members, through the provision of information and advice on good practice, safe working, and enforcement within the theatre industry. They advise on safety, planning, and good practice.

Amongst other things, this partnership will assist Guard Load Arrest in highlighting the importance of high safety standards in the theatre industry, especially with regards to equipment that is suspended at height.

To find out more about Guard Load Arrest please visit www.guardloadarrest.com or contact the knowledgeable team.

Guard Load Arrest Launches

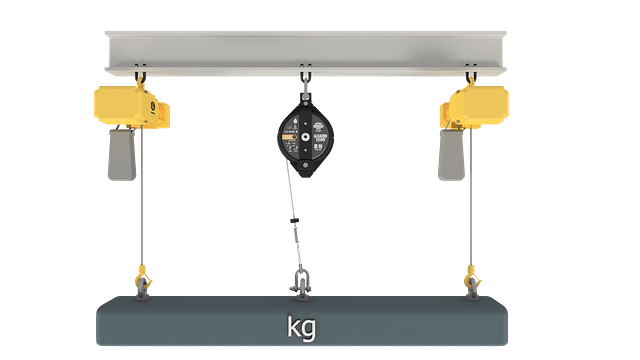

Guard Load Arrest has just launched, offering durable load arrest solutions to the entertainment and industrial sectors.

The product range offers protection from 150kg to 1500kg, and developments are already underway to expand the range even further.

One of the most common uses of load arrestors is as a secondary safeguard for chain hoists. Patrick Evans, Managing Director, explains more:

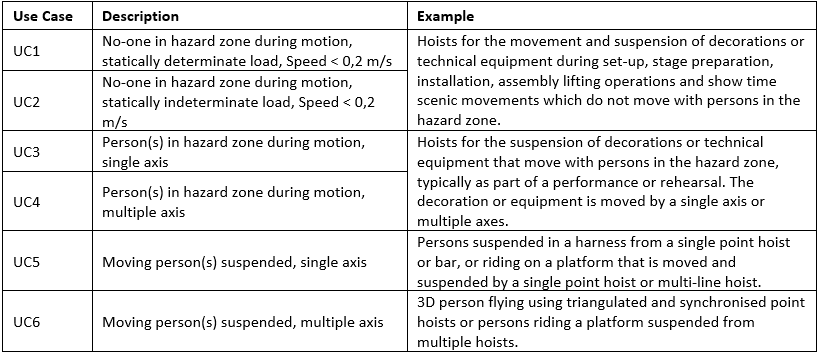

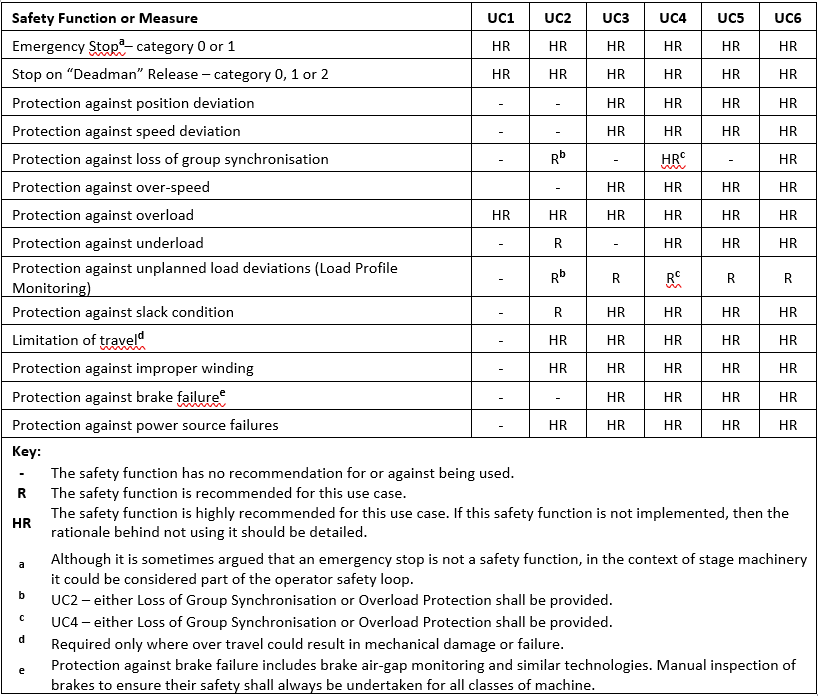

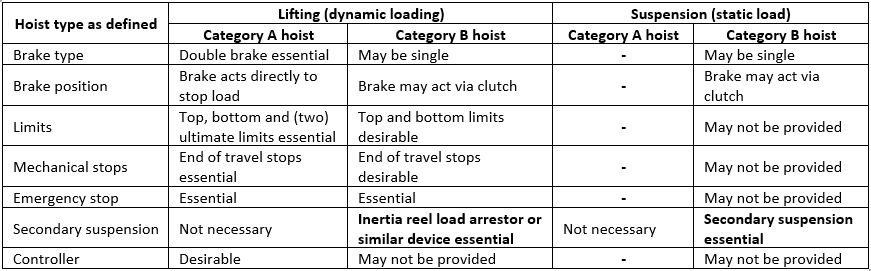

“EN 17206 stipulates that two independent safety solutions are required when installing electric chain hoists. Whether a hoist’s secondary brake provides the necessary level of safety comes down to your risk assessment, but we’re finding more and more that installers are deploying Guard units alongside hoists to provide a separate safeguard, should the primary system fail.”

Of course, electric chain hoists generally feature a safety brake that kicks-in if the primary brake fails. But what’s the back-up if the hoist’s chain or anchor fails? Patrick goes on to say:

“There are a few options available, one of which is to simply attach a fixed steel cable as a secondary safety solution. This would be extremely safe. However, increasingly users are abandoning this method due to the large cost of sending a rigger to detach and refix every time it is needed. Guard load arrestors are an alternative cost-effective option which overcomes this problem by providing a steel cable that automatically extends and retracts, following the movement of the load, without having to be detached.”

If the primary load bearing equipment fails, the Guard load arrestor will automatically stop the load falling, thereby preventing damage to the equipment and, more importantly, protecting the audience/performers below.

It’s not just the entertainment sector where Guards are being increasingly installed. Many industrial applications benefit from load arrest. Patrick elaborates:

“There are a huge number of applications where load arrestors provide an ideal safety solution. Do you lift or suspend equipment or materials that cannot be allowed to drop? If so, you should consider installing a Guard load arrest device as a safeguard in case the primary lifting equipment fails.”

“Production lines cannot afford lengthy shutdown periods to repair fallen equipment. A great example is how some car manufacturers depend on Guard load arrestors to protect key points in the production line; their engineers identified a risk of heavy equipment shutting-off during use, which could result in an uncontrolled fall to the workshop floor. This is where Guard Load Arrest steps in. A Guard load arrestor positioned at the right spot will automatically catch falling equipment, stopping it hitting the floor. Our products are so versatile and dependable, they’re even deployed as a safeguard for lifting radioactive materials in a certain UK nuclear power facility!”

Guard Load Arrest’s list of customers is already impressive, including O2 Academy Group and Jaguar Land Rover.

The new Guard range is available now.

We Have Lift Off!

Hello World.

Meet Guard Load Arrest.

Watch this space for news and articles about the range of Guard Load Arrestors.