The complexities and costs involved in managing and maintaining rigging in exhibition venues can be immense. Throughout the industry, rigging and safety managers rely on Guard load arrestors to simplify systems and reduce costs.

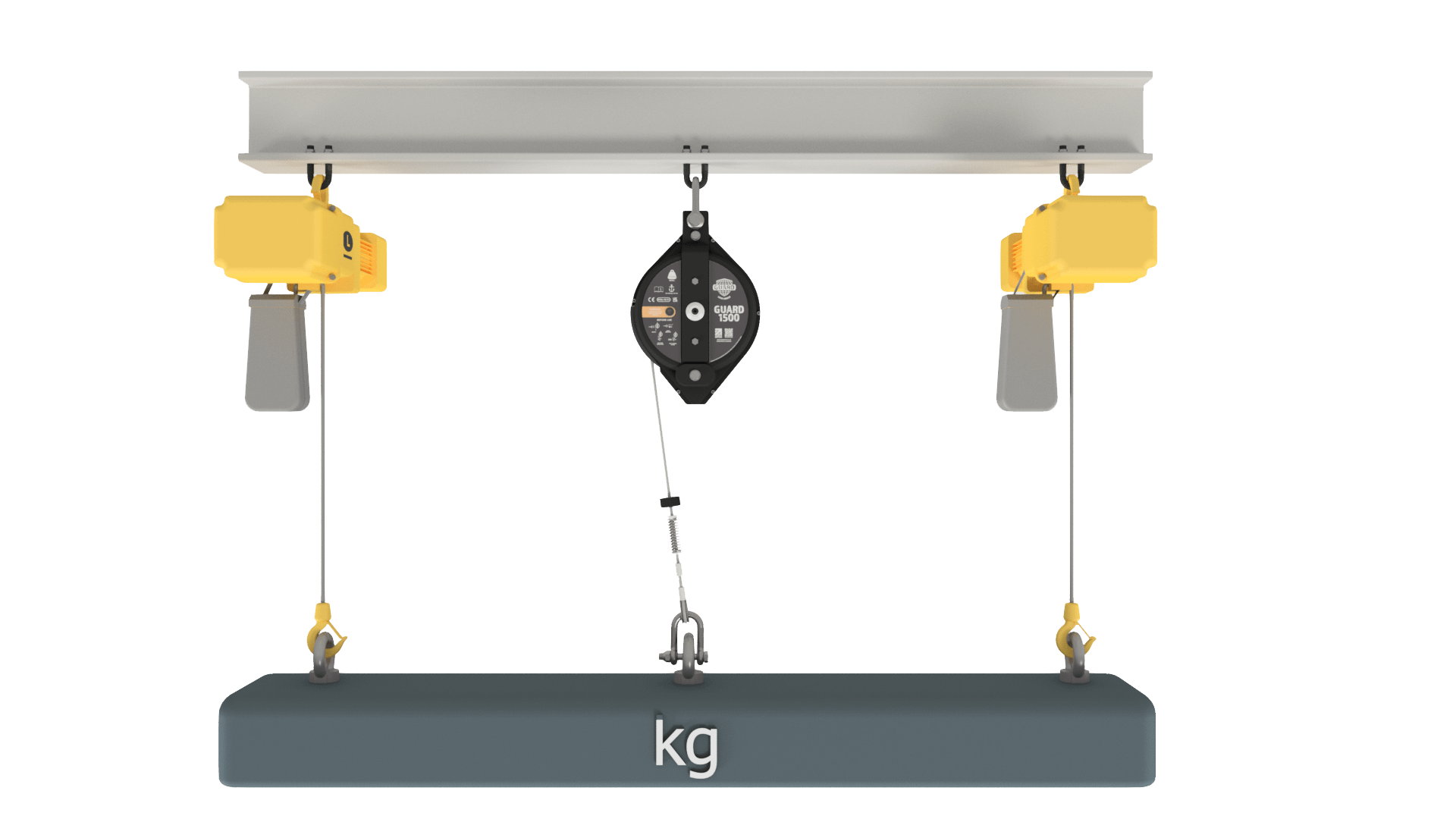

EN17206 stipulates that two independent safety solutions are required when installing electric chain hoists / motors. Whether a motor's secondary brake provides the necessary level of safety comes down to your risk assessment, but we are finding more and more that installers are deploying Guard Load Arrest units alongside motors to provide a separate safeguard, should the primary system fail.

Chain hoists generally feature a safety brake that kicks-in if the primary brake fails. But what is the back-up if the motor's chain or anchor fails?

There are a few options available, one of which is to simply attach a fixed steel cable as a secondary safety solution. This would be extremely safe. However, increasingly users are abandoning this method due to the large cost of sending a rigger to detach and refix every time it is needed. Guard load arrestors are an alternative cost-effective option which overcomes this problem by providing a steel cable that automatically extends and retracts, following the movement of the load, without having to be detached.

In the below example you can see how Guard load arrestors (circled) have been used as a safeguard for a lighting and sound truss within exhibition venues. Here, two Guards are anchored above the truss, with the cables attached to the truss itself. There are another two Guards positioned above the speaker cabs. If the truss or speakers were to fall, one (or more) of the arrestors would automatically activate, thereby stopping the fall and guarding the valuable equipment and preventing potential catastrophic injury. Perfect.

Whatever you do, make sure you #GuardAgainstGravity.

View the products here.